We have always shaped our industry.

Explore our patent vault to learn more about how our rich history of research and development has shaped the energy and manufacturing industries.

Marvelous Marlex

Marvelous Marlex

In 1962, two researchers discovered a process for making polyphenylene sulfide, marketed as "Ryton." Ryton was extremely hard and durable like steel, but was light and corrosion-resistant. It was easily molded into intricate shapes for parts in computers, engines and military hardware. Five years later in 1967, Phillips researchers invented a new family of plastics known as "K-Resin." K-Resin was clear, impact-resistant and easy to process. It became an ideal material for medical devices, toys and packaging. Both Ryton and K-Resin are still sold today by CPChem.

Chemical Products

Chemical Products

Phillips' success stemmed from its ability to add value to raw hydrocarbons – the oil, natural gas and natural gas liquids it discovered and produced. The company's development of chemicals began with the production of synthetic rubber and carbon black in the 1930s, and broadened into chemicals that are components of a variety of products, including insect repellents, detergents and even the world's first oil-based, odorless paint.

15,000th Patent

15,000th Patent

In 1998, Phillips was awarded its 15,000th patent. The milestone nets out to nearly one patented innovation each working day in company history. As the New York Times put it: "Phillips researchers – along with others in the industry – have concocted an array of substances that touch virtually every aspect of life, from hair washing to national security."

Chemical Engineering

Chemical Engineering

Achievement Awards

Phillips was three times the recipient of the Chemical Engineering Achievement Award, the highest honor in the field of chemical engineering, for:

- Contributions to the development of synthetic rubber during World War II in 1943.

- Accomplishments in the development of high-abrasion carbon black and contributions to the development of cold rubber in 1951.

- Pioneering applications for chemical engineering processes and principles in the metallurgy of atomic-age metals in 1957.

Natural Gas Liquids

Phillips was one of the first companies to recognize that liquids could be extracted from natural gas vapors and turned into valuable products. Gas and natural gas liquids (NGL) played a pivotal role in the company's growth. From 1924 until 1995, Phillips was the nation's largest NGL producer. (Patent #152062)

Refining Modernization

Refining Modernization

In the late 1970s and early 1980s, Phillips upgraded its Sweeny and Borger refineries in Texas enabling them to handle the tough-to-process heavy and sour crude oils. The result: Phillips became one of the industry's best at converting lower-cost raw material into high-quality products.

Transporting LNG

Transporting LNG

After becoming the first company to be given permission to drill in Alaska, Phillips completed a massive, LNG project in 1969. The project transported LNG on custom-made vessels that traveled 3,250 miles to Japan. This marked the first time anyone had commercially exported LNG from the United States. Phillips' Kenai LNG project revolutionized the commercial LNG industry and demonstrated LNGs potential to the world.

Multi-Product Pipeline

In 1930, Phillips began work on the single most ambitious project the company had yet undertaken: a new type of pipeline stretching 680 miles from the Texas Panhandle to East St. Louis, Ill. Although many in the industry were skeptical, Phillips engineers built a single pipeline to move many products, such as gasoline, kerosene and diesel oil in separate batches. The same pipelining technique is still used today to deliver pure products from refineries to distribution centers around the world.

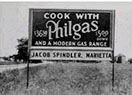

Philgas

Philgas

Phillips wanted to find a use for the propane generated from processing natural gas liquids. A company research team determined propane, or "Philgas," was an ideal fuel for home

cooking. By 1929, Phillips propane was on the market and thousands of homes were cooking with Philgas.

K Resin and Ryton

K Resin and Ryton

In 1962, two researchers discovered a process for making polyphenylene sulfide, marketed as "Ryton." Ryton was extremely hard and durable like steel, but was light and corrosion-resistant. It was easily molded into intricate shapes for parts in computers, engines and military hardware. Five years later in 1967, Phillips researchers invented a new family of plastics known as "K-Resin." K-Resin was clear, impact-resistant and easy to process. It became an ideal material for medical devices, toys and packaging. Both Ryton and K-Resin are still sold today by CPChem.

The Ekofisk Block

The Ekofisk Block

Ekofisk, the first major oil discovery in Western Europe, was followed by five other large discoveries in the North Sea. Phillips built the world's largest offshore complex in order to gather, process and transport oil and natural gas from the fields. Ekofisk Center consisted of a mid-sea network of 27 platforms, with oil flowing through a 220-mile pipeline to the United Kingdom and natural gas moving through a 275-mile pipeline to Germany. At the height of development, as many as 2,000 men and women worked offshore in this multibillion dollar "city in the sea."

< Back